Transforming Your Business Environment with Industrial Air Dehumidifiers

In the realm of business operations, maintaining optimal environmental conditions is critical. One often overlooked aspect is humidity control. Excessive moisture can wreak havoc in industrial settings, leading to decreased productivity, damage to equipment, and even health risks for employees. This is where the industrial air dehumidifier comes into play, proving itself to be an indispensable tool for businesses across various sectors.

Understanding the Need for Industrial Dehumidification

Whether you are in manufacturing, warehousing, or any other humidity-sensitive industry, understanding why humidity control is necessary can be the difference between success and failure. Here are some reasons:

- Equipment Longevity: High humidity levels can lead to corrosion and deterioration of machinery. An industrial air dehumidifier helps protect critical equipment, reducing maintenance costs and prolonging lifespan.

- Product Quality: Many products, especially in the food, textile, and electronics industries, require specific humidity levels for optimal quality. Dehumidifiers ensure that moisture does not compromise product integrity.

- Employee Health: Excess humidity can lead to mold growth, which poses health risks to employees. Maintaining a controlled environment mitigates these risks and promotes a healthier workplace.

Types of Industrial Air Dehumidifiers

Not all dehumidifiers are created equal. Understanding the different types of industrial air dehumidifiers will help you make an informed decision on which is best suited for your business needs:

1. Desiccant Dehumidifiers

These units use a desiccant material to absorb moisture from the air. They are ideal for environments with low temperatures and are commonly used in sensitive applications such as pharmaceuticals and food processing.

2. Refrigerant Dehumidifiers

Most industrial dehumidifiers operate on refrigeration technology, cooling air to below its dew point, causing moisture to condense. This type is suitable for large spaces like warehouses or production facilities.

3. Thermo-electric (Peltier) Dehumidifiers

These compact units are perfect for smaller spaces and operate quietly, making them ideal for retail environments or office use. However, they may not be as effective in larger industrial areas.

Key Benefits of Implementing an Industrial Air Dehumidifier

The implementation of an industrial air dehumidifier provides a myriad of benefits for businesses looking to improve their operations:

1. Improved Air Quality

By reducing humidity levels, dehumidifiers help to minimize allergens and mold spores, resulting in better overall air quality. Improved air quality contributes to enhanced employee productivity and morale.

2. Reduced Energy Costs

Lower humidity levels can lead to decreased air-conditioning costs. Most HVAC systems do not adequately control humidity, resulting in excess energy consumption. An industrial dehumidifier works in tandem with HVAC systems to enhance energy efficiency.

3. Compliance with Industry Standards

Many industries have strict regulations regarding humidity control. Utilizing an industrial air dehumidifier helps you meet these standards, avoiding costly fines and potential legal issues.

Factors to Consider When Choosing an Industrial Air Dehumidifier

Selecting the right dehumidifier requires careful consideration of several factors:

- Capacity: Measure the cubic footage of the space to determine the required dehumidification capacity, usually measured in pints per day.

- Operating Environment: Consider temperature ranges, as some units perform better in extreme conditions.

- Portability: Determine whether a stationary system or a portable unit better suits your operational needs.

- Drainage Options: Decide between manual drainage or continuous drainage for efficiency in larger setups.

Case Studies: Success Stories of Industrial Air Dehumidifiers

Many businesses have experienced the transformative effects of implementing an industrial air dehumidifier. Let’s explore a few real-world examples:

Case Study 1: Food Processing Facility

A food processing facility faced challenges with humidity leading to mold growth on products. By installing several industrial air dehumidifiers, they reduced humidity levels efficiently. The result was a significant decrease in spoilage rates, compliance with health regulations, and improved product quality.

Case Study 2: Textile Manufacturing

A textile manufacturer found that high humidity affected their production processes and product quality. After incorporating dehumidification, they noted marked improvements in fabric processing and reduced instances of product returns due to quality issues.

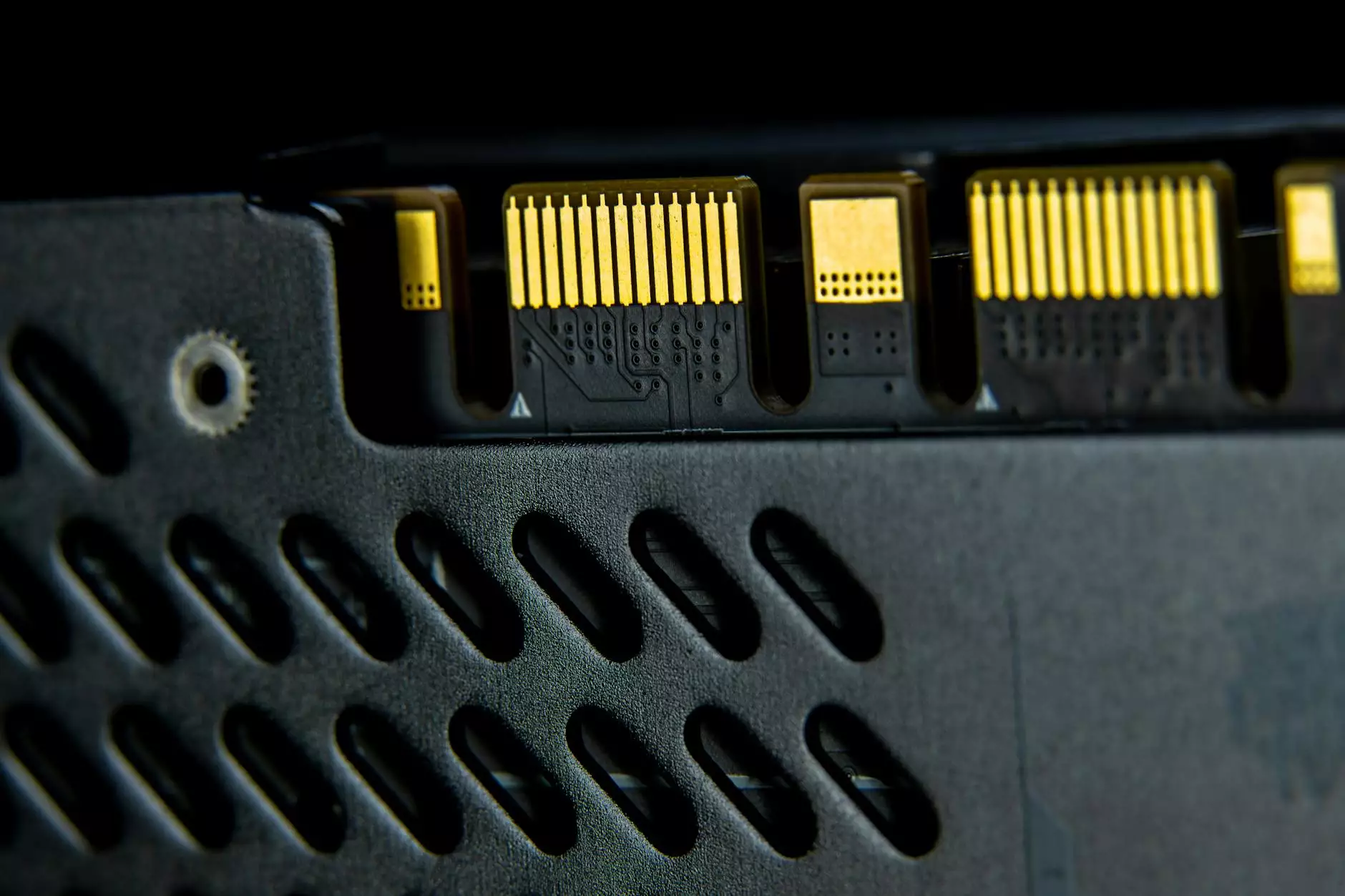

Case Study 3: Electronics Manufacturer

The electronics industry is incredibly sensitive to moisture. A manufacturer experiencing issues with product defects implemented a robust dehumidification system. This led not only to reduced defect rates but also to significant cost savings in warranty repairs.

Maintenance and Care of Industrial Air Dehumidifiers

To ensure optimal performance, regular maintenance of your industrial air dehumidifier is essential. Here are some maintenance tips:

- Regular Cleaning: Dust and debris can block filters and vents, reducing efficiency. Clean filters regularly and replace them according to manufacturer specifications.

- Inspect Drainage Systems: Check for leaks or blockages in drainage systems to ensure proper functioning.

- Professional Servicing: Schedule professional inspections and servicing to identify potential issues before they become significant problems.

Conclusion: Invest in an Industrial Air Dehumidifier Today

The benefits of an industrial air dehumidifier are undeniable. By investing in this critical piece of equipment, businesses can enhance productivity, protect assets, and create a safer, more comfortable working environment. At Climatronics, we offer a wide range of top-quality industrial dehumidifiers tailored to meet the specific needs of your business. Don't let humidity sabotage your success; reach out to us today for expert advice and solutions that work.

Frequently Asked Questions

What is the ideal humidity level for industrial settings?

The ideal humidity level generally ranges from 30% to 50%, depending on the specific industry and application.

How do I know if my facility needs a dehumidifier?

Signs include visible mold, musty odors, condensation on surfaces, and increased rates of equipment failure or product spoilage.

Can I use a residential dehumidifier in an industrial setting?

It is not advisable. Residential units lack the capacity and durability required for industrial environments.