Discover the Best Crankshaft Manufacturers in China

When it comes to sourcing high-quality crankshafts, China stands out as the leading hub for manufacturing excellence. With a continuously evolving industrial landscape, the country has established itself as a home to some of the top crankshaft manufacturers in China. In this article, we will delve into the importance of crankshafts, the manufacturing technologies employed, key suppliers, and how you can ensure you partner with the best of the best.

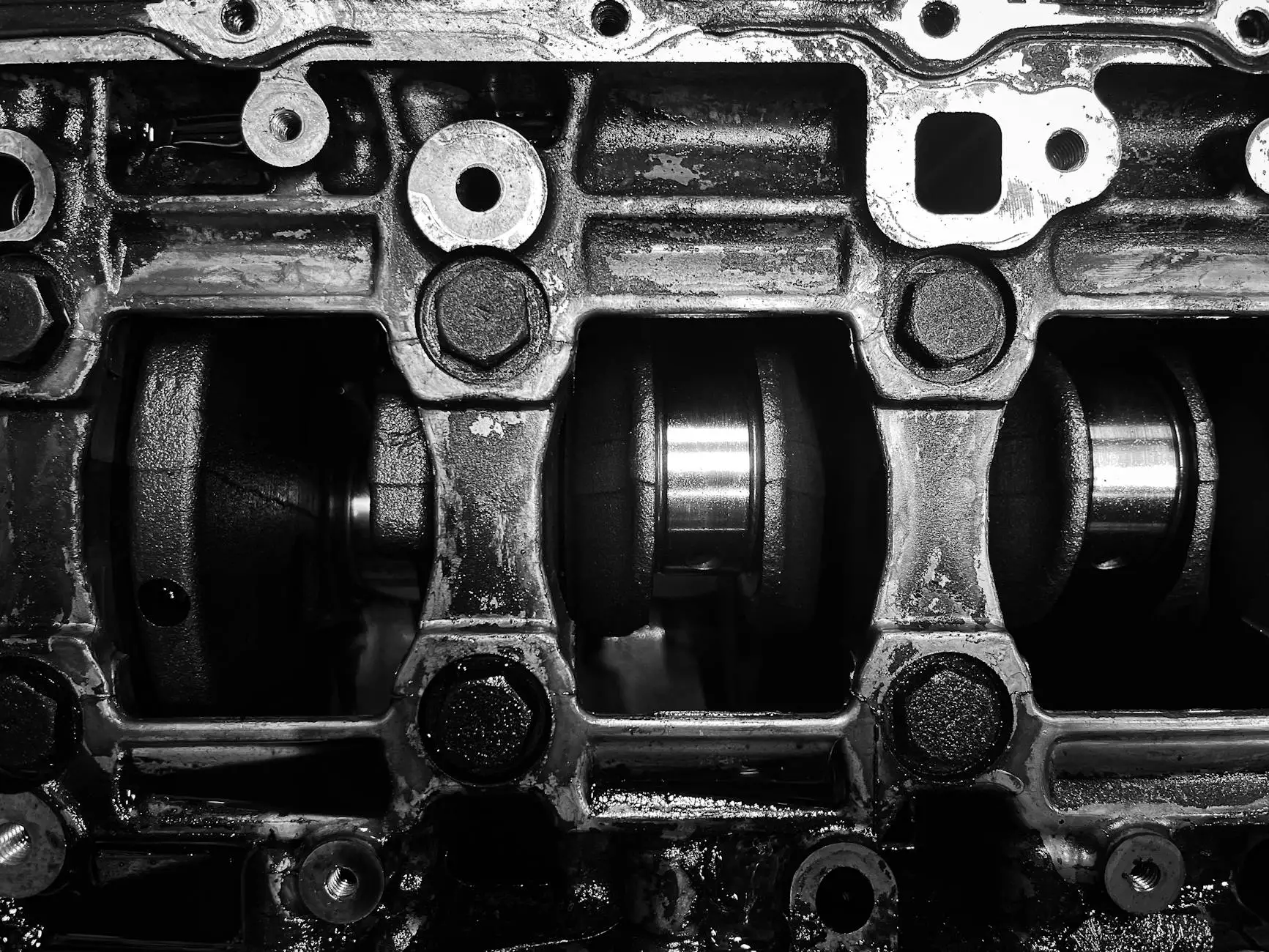

The Importance of Crankshafts in Diesel Engines

At the heart of any diesel engine is the crankshaft, an essential component that converts the linear motion of pistons into rotational motion. This process is crucial for the engine’s power generation and overall functionality. Here's why crankshafts are indispensable:

- Power Generation: Crankshafts are vital for converting energy generated from combustion into usable power.

- Durability: A high-quality crankshaft ensures longevity and reliability in diesel engines, reducing maintenance costs.

- Performance: Well-manufactured crankshafts enhance engine performance, improving efficiency and responsiveness.

Technological Advancements in Crankshaft Manufacturing

The crankshaft manufacturing industry in China has seen significant technological advancements that contribute to the production of superior quality products. Here are some notable techniques and processes employed:

1. CNC Machining

Computer Numerical Control (CNC) machining allows for precise fabrication of crankshafts. This technology ensures that every component meets stringent tolerances, thus enhancing engine performance.

2. Forging Technology

Many top manufacturers utilize forging techniques, wherein steel is heated and shaped under pressure. This method produces stronger and more reliable crankshafts that can withstand high-stress conditions.

3. Heat Treatment Processes

Heat treatment processes such as quenching and tempering increase the hardness and strength of crankshafts, making them more resilient to wear and tear. This treatment is crucial for the longevity of engines.

Key Crankshaft Manufacturers in China

Choosing the right supplier is essential for acquiring high-quality crankshafts. Below are some of the leading crankshaft manufacturers in China known for their excellence and reliability:

1. Jiangsu Jiejing Group

Jiangsu Jiejing Group is renowned for producing high-performance crankshafts suitable for various diesel engines. Their use of advanced manufacturing technologies ensures the production of top-quality products.

2. Shanghai Jinfu Industry Co., Ltd.

Specializing in high-grade automotive parts, Shanghai Jinfu focuses on precision and quality control in its crankshaft manufacturing processes, offering products that excel in durability and performance.

3. Chongqing Puzhou Machinery Co., Ltd.

With decades of experience, Chongqing Puzhou Machinery produces crankshafts that meet international standards, ensuring compatibility with various engine types while providing exceptional performance.

4. Weichai Power Co., Ltd.

As one of China’s leading engine manufacturers, Weichai Power also excels in crankshaft production, leveraging its extensive research and development capabilities to innovate and improve its offerings continuously.

How to Choose the Right Crankshaft Supplier

Selecting the right manufacturer is crucial. Here are some factors to consider when choosing crankshaft manufacturers in China:

- Quality Certifications: Ensure that the manufacturer has relevant quality certifications, such as ISO 9001, which indicates adherence to international quality standards.

- Industry Experience: Look for suppliers with a proven track record and extensive industry experience in producing crankshafts.

- Customer Reviews: Reviews from previous clients can provide insights into the reliability and performance of the supplier's products.

- Research and Development: A manufacturer that invests in R&D is likely to offer innovative solutions and improvements in crankshaft technology.

- After-sales Support: Robust after-sales support is critical. Choose suppliers who offer good warranty terms and customer assistance.

Understanding Pricing and Market Trends

The pricing of crankshafts largely depends on various factors, including materials used, manufacturing processes, and overall demand in the market. Here are some insights into the current trends:

1. Material Costs

Fluctuations in material costs, particularly steel and alloys, can impact the pricing of crankshafts. Manufacturers that can efficiently manage their supply chain often provide better pricing.

2. Global Competition

With many countries competing in the crankshaft manufacturing sector, China maintains a competitive edge due to its advanced technology and cost-effective production methods.

3. Demand for High-Performance Parts

As automotive and industrial applications demand higher efficiency, suppliers are increasingly investing in advanced materials and technologies, leading to a rise in prices for high-performance crankshafts.

The Future of Crankshaft Manufacturing in China

The future of crankshaft manufacturing in China looks promising. Several trends are likely to shape the industry:

- Increased Automation: As manufacturers adopt advanced automation, production efficiency will increase, leading to cost savings and enhanced quality control.

- Advancements in Materials: The development of new, lighter, and stronger materials will enable the production of crankshafts that offer improved performance and efficiency.

- Sustainability Initiatives: Manufacturers are increasingly focusing on sustainable practices, including waste reduction and environmentally friendly materials, to meet global standards.

- Customization: There is a growing demand for customized crankshafts designed to meet specific engine requirements, leading manufacturers to offer tailored solutions.

Conclusion

In conclusion, sourcing from the best crankshaft manufacturers in China is essential for ensuring the quality and reliability of diesel engines. With advancements in technology, a rich pool of experienced suppliers, and a commitment to quality, China is at the forefront of crankshaft manufacturing. By choosing the right partner, businesses can benefit from superior products that enhance engine performance and longevity. Explore your options and connect with the leaders in the market to secure the best crankshafts for your needs.

Contact Us

If you're looking for premium diesel engine parts, including crankshafts, client-diesel.com can connect you with some of the best suppliers in the industry. Our expertise in sourcing and manufacturing ensures you receive only the highest quality products tailored to your business needs.