Comprehensive Guide to Vacuum Press Membranes: Unlocking Innovation in Business

In the dynamic world of manufacturing and industrial processing, *vacuum press membranes* have become indispensable tools for achieving precision, quality, and efficiency. As industries strive to optimize their production lines, improve product quality, and reduce operational costs, the strategic employment of high-performance membranes specifically designed for vacuum pressing has gained paramount importance. This extensive guide delves into the nuanced aspects of *vacuum press membranes*, exploring their types, applications, benefits, and how sourcing them from reputable sellers like silicone-membranes.eu can revolutionize your business operations.

Understanding Vacuum Press Membranes: The Heart of Precision Manufacturing

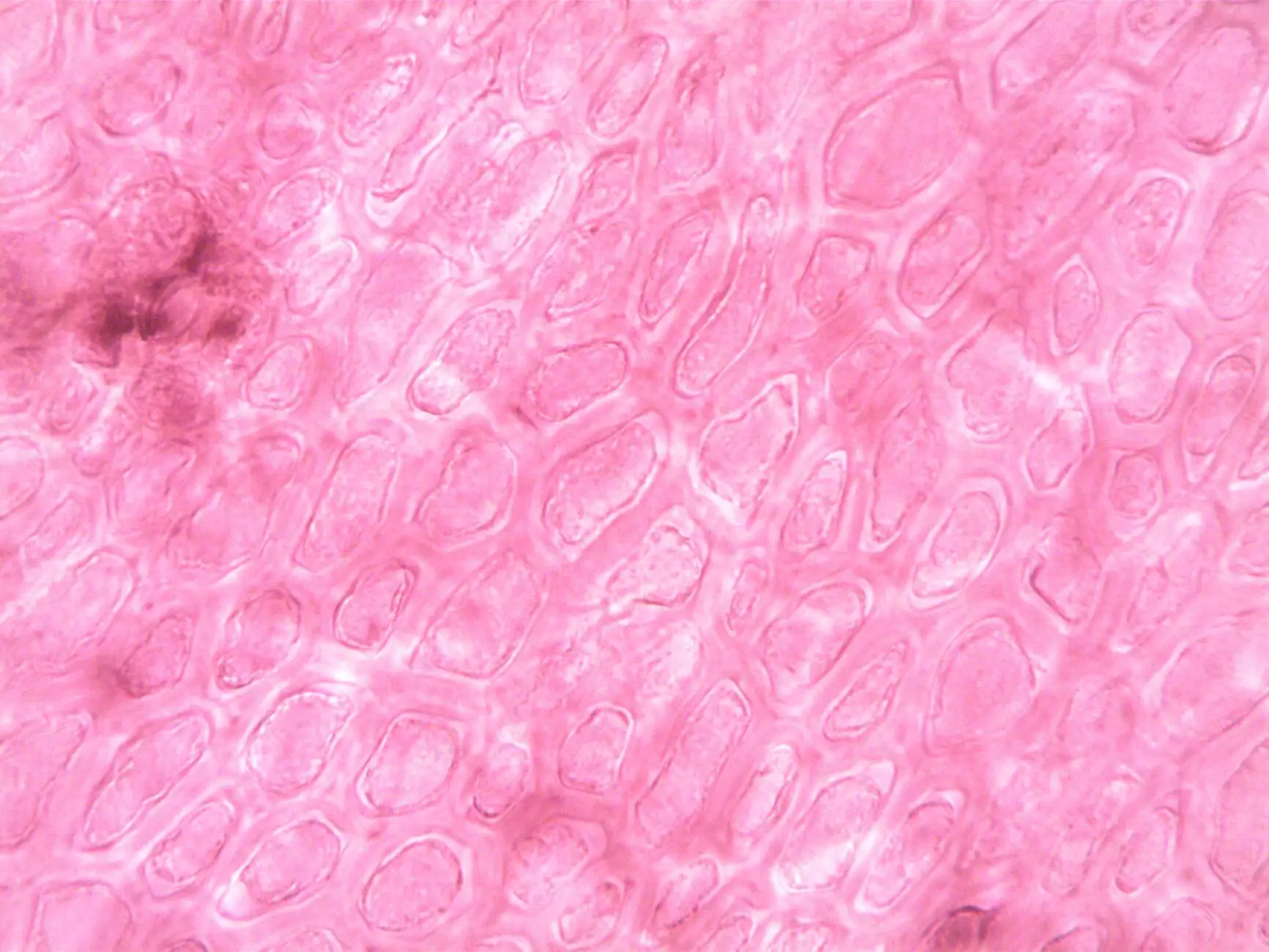

At the core of many advanced manufacturing processes is the *vacuum press membrane*. These membranes are essential components that create a controlled, evenly distributed pressure environment during pressing, forming, and curing processes. Their primary function is to ensure uniform contact between materials, eliminate air pockets, and streamline complex shaping tasks across various industries such as textiles, composites, woodworking, and artificial leather production.

Types of Vacuum Press Membranes: An In-Depth Overview

There are several types of *vacuum press membranes*, each tailored to meet specific industry needs, operational conditions, and material compatibility. Selecting the right type is crucial for optimizing performance and ensuring longevity.

Silicone Membranes

Known for their exceptional flexibility, high-temperature resistance, and chemical inertness, silicone membranes are among the most popular options in the market. They are highly durable, maintain their elasticity over a wide temperature range, and are ideal for applications involving heat curing and frequent cycles. Their non-stick properties make them suitable for delicate materials and complex shapes, ensuring seamless operation.

Rubber Membranes

Rubber membranes are valued for their robustness and cost-effectiveness. They offer excellent resilience under consistent pressure and are commonly used in applications requiring high mechanical strength and chemical resistance. Available in various formulations, rubber membranes can withstand aggressive chemicals and abrasive conditions, making them suitable for industrial settings demanding durability.

Composite and Hybrid Membranes

To achieve optimal performance, some manufacturers opt for composite or hybrid membranes, combining materials like silicone and rubber to leverage the advantages of both. These membranes offer tailored properties such as enhanced flexibility, chemical resistance, and temperature tolerance, suited for specialized applications.

Application Fields: How Vacuum Press Membranes Drive Business Success

The versatility of *vacuum press membranes* makes them indispensable across diverse sectors. Their ability to improve process accuracy, reduce waste, and speed up production cycles directly correlates with the profitability and competitiveness of businesses.

Furniture and Composite Manufacturing

In the furniture industry, vacuum press membranes are used to shape and bond veneers, laminates, and composite materials efficiently. They ensure tight conforming to complex molds, resulting in high-quality, uniform products with minimal defects.

Automotive and Aerospace Industries

For the automotive and aerospace sectors, *vacuum press membranes* facilitate the fabrication of lightweight composite parts, panels, and interiors. They contribute to high-precision manufacturing essential for safety, performance, and aesthetic excellence.

Artificial Leather and Textiles

In the production of artificial leather and textiles, these membranes enable even pressing and curing, ensuring consistent quality and appearance. Their ability to adapt to delicate materials enhances product quality and customer satisfaction.

Electronics and Packaging

Specialized *vacuum press membranes* assist in creating vacuum-sealed packaging, as well as shaping electronic components. Their precision helps prevent contamination and ensures the integrity of sensitive items.

The Benefits of Implementing High-Quality Vacuum Press Membranes

Investing in top-tier *vacuum press membranes* yields numerous advantages that can significantly impact business performance:

- Enhanced Product Quality: Achieve uniform pressure distribution and precise shaping, leading to superior finished goods.

- Increased Efficiency: Faster cycle times and reduced downtime improve overall productivity.

- Cost Savings: Durability and longevity of high-quality membranes reduce replacement costs and waste.

- Versatility: Adaptability to various materials and processes broadens application scope.

- Environmental Benefits: Efficient usage and reduced waste support sustainable manufacturing practices.

Choosing the Right Silicone Membrane for Sale: A Key Business Decision

When it comes to sourcing *silicone membranes for sale*, it's critical to consider factors such as manufacturing quality, material specifications, and supplier reputation. Leading providers like silicone-membranes.eu offer a diverse range of high-grade membranes tailored to different industrial needs, ensuring customers receive durable, reliable, and cost-effective solutions.

The Role of Rubber Membrane Shop in Supplying Quality Products

A reputable rubber membrane shop provides not only a wide selection of membranes but also expert guidance on choosing the right type based on your specific process requirements. Access to advanced manufacturing techniques, customization options, and excellent after-sales service make these shops vital partners in ensuring your operations run smoothly.

Innovations and Future Trends in Vacuum Press Membranes

As industries continue evolving, so do *vacuum press membranes*. Emerging technologies include:

- Self-healing membranes: Incorporating materials that automatically repair small damages to extend service life.

- Smart membranes: Embedded sensors to monitor pressure and temperature, providing real-time data for process optimization.

- Eco-friendly materials: Biodegradable and low-impact formulations aligning with sustainable manufacturing goals.

These innovations promise increased efficiency, sustainability, and smarter manufacturing ecosystems.

Maximizing Business Growth with the Right Membrane Solutions

By integrating high-quality *vacuum press membranes*, businesses can unlock new levels of productivity, product excellence, and cost savings. Establishing partnerships with suppliers specializing in silicone membranes and rubber membranes ensures access to cutting-edge products that are resilient and adaptable. This strategic investment not only enhances operational capabilities but also positions your business ahead of competitors in an increasingly demanding market.

Conclusion: Elevate Your Manufacturing with Superior Vacuum Press Membranes

In conclusion, the significance of *vacuum press membranes* in today’s manufacturing landscape cannot be overstated. Their role in achieving precision, efficiency, and quality makes them a vital asset for industries seeking growth and innovation. Whether you're exploring *silicone membranes for sale* or sourcing from a trusted *rubber membrane shop*, selecting the right membranes is a decisive factor in your business success. Embrace these advanced solutions, leverage the expertise of reputable suppliers like silicone-membranes.eu, and set your enterprise on a trajectory of excellence and sustainability.